Transforming a Chaotic

Supply Chain

into a Competitive Edge

About the

project

Mahajan Industrial Supplies, a 40-year-old B2B supplier of industrial tools and raw materials, was struggling despite having a solid reputation. While their revenue looked stable, profit margins were eroding, and customer complaints were rising.

- Delivery delays were increasing due to unpredictable demand.

- Stockouts and overstocking were bleeding working capital.

- Logistics costs were out of control due to inefficient dispatching.

The owner believed rising competition was the problem. The real issue? Mahajan’s supply chain was running on guesswork in a data-driven world. Instead of increasing sales, I optimized the entire supply chain using AI-powered forecasting, dynamic inventory management, and cost-effective logistics automation.

Key Solutions Implemented

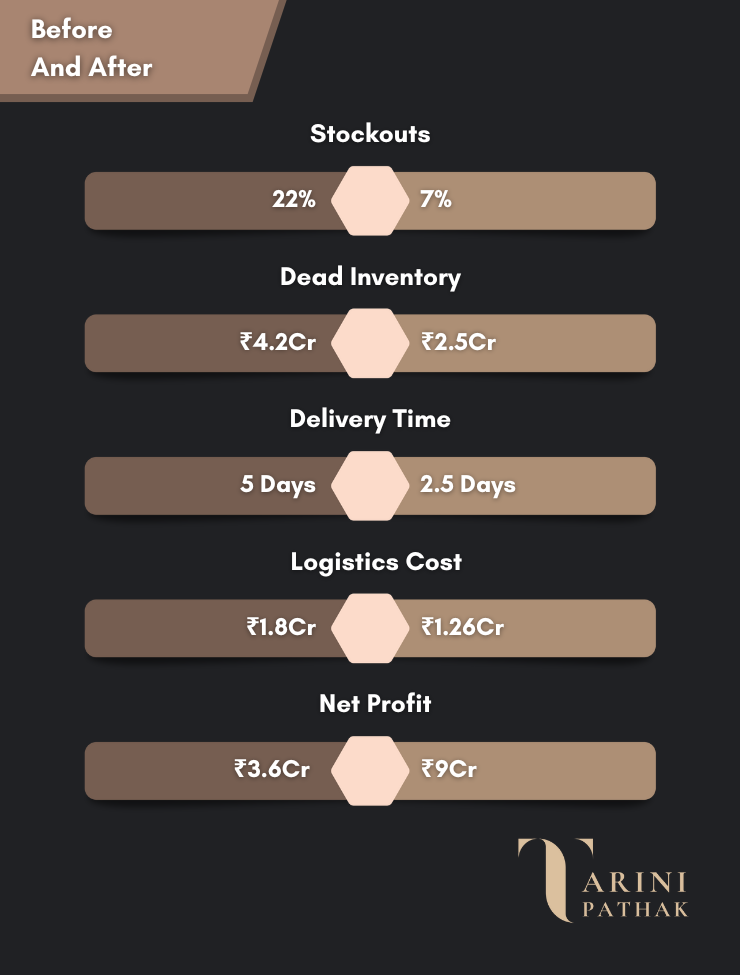

- AI-Powered Demand Forecasting – Predictive analytics reduced stockouts by 65% and cut excess inventory costs by 40%.

- Dynamic Inventory & Supplier Management – Introduced real-time demand tracking, ensuring optimal stock levels at all times.

- Logistics Route Optimization – AI-based dispatching reduced delivery times by 50%, lowering logistics expenses by 30%.

Skillset Applied

Predictive Analytics & AI Forecasting

Profitability Analysis & Business Strategy

Logistics Automation & Cost Reduction

Inventory & Demand Optimization

With zero additional marketing spend, Mahajan Industrial Supplies increased its net profit by 2.5x in just seven months—not by selling more, but by operating smarter.

Insights from the project

- Unstructured supply chains are invisible profit killers. Mahajan was losing ₹3 crore annually due to inefficiencies, not competition.

- Demand isn’t unpredictable—it’s just misunderstood. AI models revealed repeated purchasing patterns that the company had ignored.

- Businesses don’t fail from lack of customers, but from lack of control. The problem wasn’t demand, but supply chain chaos.